what we give

Value Added Services

Value Added Services

3-D Precision Machine is ISO 9001:2015/AS9100 Rev D Certified by NSF-ISR, ITAR Registered, manufacturing company that provides our customers with value added advantages including:

These valuable services separate and elevate 3-D Precision Machine from a traditional machine shop to a seamless outsourcing partner, ensuring proven, reliable repeatability. Because we house everything under one roof, a high quality end result is guaranteed.

Engineering Services:

With our onsite partner 3-D Engineering Corp, a product development/research and development company, we provide the full lifecycle of engineering services to our customers including concept development, FEA analysis, stress analysis, design, CAD drawings and reverse engineering.

Assembly and Integration:

3-D Precision Machine manufactures parts per our customer’s specifications and many times assembles and integrates these parts into new or existing assemblies, subassemblies and working units. Our 14,000 sq. ft. facility provides the perfect environment for turnkey production of quality inspected assemblies, sub assemblies, and working units. Our customers enjoy the benefits of our full service, cost effective solution to manufacturing.

Outside Processes:

Anodize, passivation, electroless nickel, gold plate, chemical conversion coating, paint/powder coat, heat treat, electropolish, Tiodize, Dicronite, other proprietary processes.

Inventory Program:

3-D Precision Machine checks all finished goods into a secured inventory room using their custom inventory software program. The finished goods, including parts, assemblies and subassemblies not needed by the customer immediately are electronically cataloged and stored in our locked inventory room. This allows our customers the surety that their parts are safely segregated and stored by part number and are easily retrievable.

Software:

With our onsite partner 3-D Engineering Corp, a product development/research and development company, we provide the full lifecycle of engineering services to our customers including concept development, FEA analysis, stress analysis, design, CAD drawings and reverse engineering.

Equipment

Meet our Management Team

Recent News

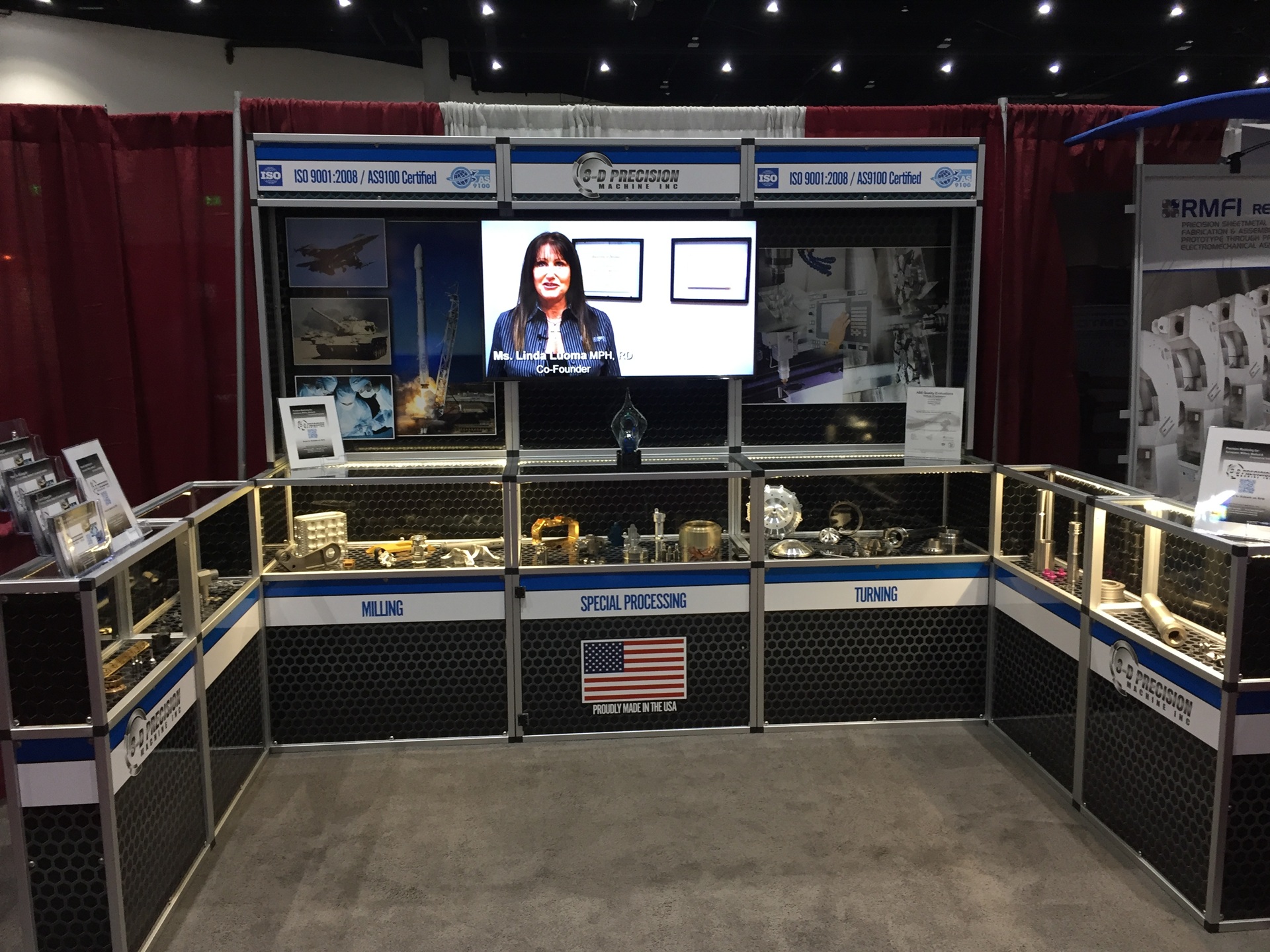

3-D Precision Machine, Inc. Exhibits at the 2019 Space Expo:

3-D Precision Machine is exhibiting at the 2019 Space Tech…

Two Industries Joined: CNC Milling & 3D Printing

3D printing and CNC milling accomplish the same things; creating…